Manufacturer of furnace of kiln of industry of _ of equipment of furnace of kiln of _ of industrial

Well-known, Industrial kiln furnaceUse liquid fuel, moving operation is convenient, small to environmental pollution. The liquid fuel that industrial kiln furnace uses can be derv, crude oil and heavy oil, but great majority is use heavy oil.

Our country crude oil contains candle much, viscosity is big, the freezing point of heavy oil is in commonly30℃ above. That is to say, most heavy oil all is in caky condition below normal temperature. Mix for pressure boost carry, improve pulverization performance, when use, should go to heavy oil warm-up90-120℃ . Heavy oil fastens wide heat up in a steamer to divide fuel, all sorts of among them hydrocarbons have different boiling point. Gush drips into the oil of the chamber of a stove or furnace, temperature lifts gradually, composition of low boiling point evaporates above all, composition of high boiling point is increasing in the rest droplet. The temperature of oil bead is then higher and higher. The splitting decomposition temperature that should reach fuel (general prep above600℃ ) when, oil bead splitting decomposition, generate bigger charcoal bead. So with normally photograph of light oil fuel is compared, when burning heavy oil, of carbon black generate more outstanding. In addition, fuel steam is in high temperature is anoxic also meet below the condition splitting decomposition, generate relatively petty charcoal bead.

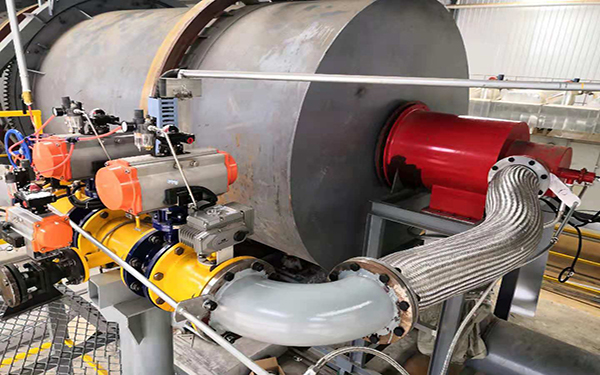

Popularly says, if enough high temperature and enough air can maintain in the second half ministry of the chamber of a stove or furnace, the charcoal bead that already generated but farther burn-up. Black smoke is formed in discharging atmosphere otherwise, become contaminative source. Because this is when design of industrial kiln furnace, should make sure heavy oil pulverization is good on one hand, avoid liquid state the splitting decomposition of oil bead. Use pneumatic spray head more for pulverization of this heavy oil, its pulverization medium can choose vapour or air according to particular case. On the other hand, want to allocate the air that enters the chamber of a stove or furnace appropriately, the oily mist inside furnace of protective gush person all can achieve enough air in combustion early days and later period, as can good as fuel mix. It is very important to because this is reasonable,be chosen or design register.

Above isManufacturer of industrial kiln furnaceThe liquid fuel knowledge that the industrial kiln heat that energy-saving equipment limited company gives Yue Yang far east everybody introduction uses, my company is offerred for broad client wholeheartedly high grade and reliableKiln furnace equipmentServe with high grade technology, let us hand in hand act vigorously is entered, achieve happiness in all tomorrow!

- Other Information

- What is the difference between a fu

- What is the condition of boiler wat

- Explanation of boiler related terms

- How do the accessories of the combu

- What is the principle of a fuel com

- Precautions for installing the burn

- Detailed discussion on the system s

- Characteristics of flames during no

- Classification and characteristics

- Preparation and precautions for on-

- What are the technical characterist

- How to select burner for gas boiler

- How do burners work for gas-fired a

- Function Of Various Parts Of Air Su

- What is the ash softening temperatu

- December 21 Christmas campaign twee